GAM 860H Automatic Drill Bit Repoint Machine

- Consistent operation for automatic cleaning, grinding, examining and put up/down materials. Make sure the grinding efficiency of Drilling.

- Accurate control of grinding quantity, increase grinding time and reduce cost.

- High precision and low vibration for emery-wheel and spindle, make sure re-point quality.

- V trough for drill bit clip, equipped with precision slot, it could change different size of drill bit in short time.

- Use keyboard to adjust and set the difference between overlap, gap, flare and taper, Simple and easy to operate.

- The AOI system can detect drill bit’s blade to ensure the quality after grinding.

| NO | GAM 860H Automatic Drill Bit Repoint Machine |

|---|---|

| Drill Diameter | ø0.1~ø0.35mm |

| Shank Diameter | ø2.0mm~Ø3.175mm(option) |

| Drill bit point angle | 120〫~140〫adjustable |

| Angle of drill point face | 5〫~30〫 |

| Outer diameter of grinding wheel | Ø75mm |

| Rotational speed of grinding wheel | 7000RPM(max) |

| The minimum feed rate | 0.5um set by computer programmer |

| Input/output the material tray | 100 pieces in 4 boxes |

| NG material tray | 100 pieces in 1 box |

| Drill bit cleanness | Times of cam cleaning in high efficiency |

| The repair and maintenance of emery wheel | Auto dressing and grinding stylization system |

| Control system | PC Base + PLC |

| Optical system | High magnification stable/zoom lens |

| The images capture system | High dpi CCD+LED light source |

| AOI system | The inspection and analysis of blade software + SPC statistics diagram |

| Dust collecting equipment | External dust collector |

| Operating system | Windows |

| Consumption of oxygen | Appr120L/min |

| The demand of air compression | 5~6kg/cm2 |

| Power source | AC220V±10% |

| General power | 2.5kw |

| Dimension(W*D*H) | 1435*1000*1675mm(Not include tricolor lamp) |

| Weight | 1200kg |

| Ability of manufacture | 0.2mm above 400UPH,0.15mm below 300UPH |

| Rate of fine | 0.2mm above 95%,0.15mm below 90% |

| Time for swapping line | In 20 minutes, if change V-type groove. In 10 minutes, if not change V-type groove. |

| Grind technics / technic date Adjustment method | Grinding quality, Flare, Taper, Overlap, Gap to be set and modified by keyboard directly. |

| Change without notice. Welcome customized request. |

|

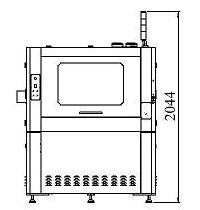

Front View

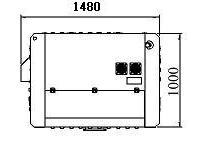

Top View

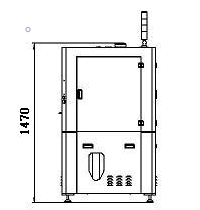

Side View

| NO | GAM 860H Automatic Drill Bit Repoint Machine |

|---|---|

| Drill Diameter | ø0.1~ø0.35mm |

| Shank Diameter | ø2.0mm~Ø3.175mm(option) |

| Drill bit point angle | 120〫~140〫adjustable |

| Angle of drill point face | 5〫~30〫 |

| Outer diameter of grinding wheel | Ø75mm |

| Rotational speed of grinding wheel | 7000RPM(max) |

| The minimum feed rate | 0.5um set by computer programmer |

| Input/output the material tray | 100 pieces in 4 boxes |

| NG material tray | 100 pieces in 1 box |

| Drill bit cleanness | Times of cam cleaning in high efficiency |

| The repair and maintenance of emery wheel | Auto dressing and grinding stylization system |

| Control system | PC Base + PLC |

| Optical system | High magnification stable/zoom lens |

| The images capture system | High dpi CCD+LED light source |

| AOI system | The inspection and analysis of blade software + SPC statistics diagram |

| Dust collecting equipment | External dust collector |

| Operating system | Windows |

| Consumption of oxygen | Appr120L/min |

| The demand of air compression | 5~6kg/cm2 |

| Power source | AC220V±10% |

| General power | 2.5kw |

| Dimension(W*D*H) | 1435*1000*1675mm(Not include tricolor lamp) |

| Weight | 1200kg |

| Ability of manufacture | 0.2mm above 400UPH,0.15mm below 300UPH |

| Rate of fine | 0.2mm above 95%,0.15mm below 90% |

| Time for swapping line | In 20 minutes, if change V-type groove. In 10 minutes, if not change V-type groove. |

| Grind technics / technic date Adjustment method | Grinding quality, Flare, Taper, Overlap, Gap to be set and modified by keyboard directly. |

| Change without notice. Welcome customized request. |

|